Żywność & Możliwość śledzenia etykiet farmaceutycznych: Jak komputer panelowy TouchThink X86 AIO w urządzeniach do etykietowania serializacji rozwiązuje kluczowe problemy

I. Przegląd rozwoju przemysłu

Food and drug safety has always been a key social issue of global concern, involving people’s health and public safety. The entire process of production, circulation and sales of every box of drugs and every piece of food must be subject to strict supervision and traceability, so as to achieve transparency in raw materials and batches as well as anti-counterfeiting.

Dlatego, implementing serialized management of products and creating “one item, one code” labels have become mandatory standards and industry consensus. This places higher requirements on labelers. They not only need to complete labeling actions at high speed, but also need to realize intelligent functions such as serialized coding, marking, labeling and verification through digital means, so as to ensure the uniqueness and accuracy of each label.

II. Wymagania dotyczące aplikacji projektowej

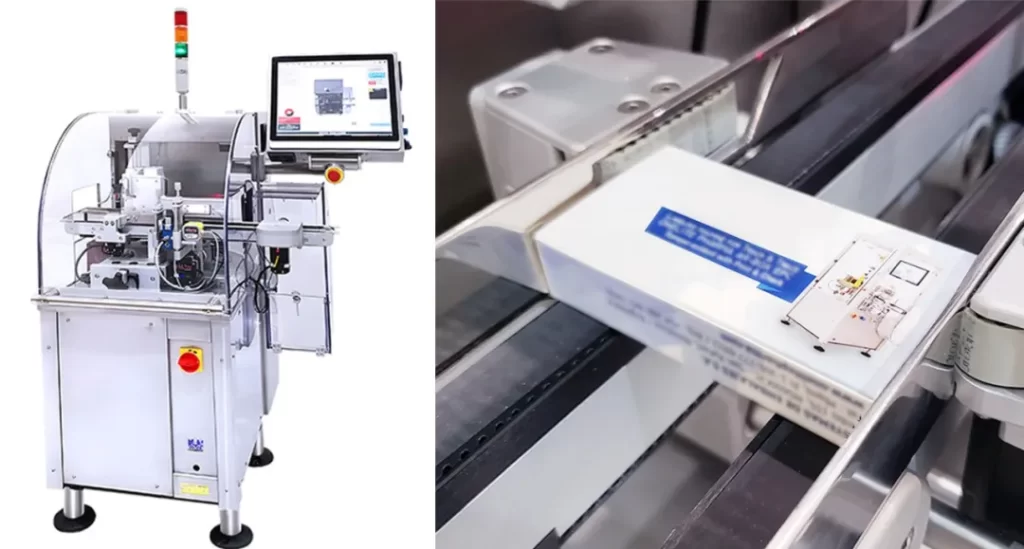

A well-known foreign packaging solution provider has developed a serialization labeler, mainly used in the pharmaceutical field. This equipment integrates functions such as inkjet printing, automatic labeling, and visual verification, all of which are managed by a single control system. Dlatego, customers need to select an industrial AIO(All-In-One) panel PC to perform upper computer management, enabling human-machine interaction and coordinating the operation of all components.

Tymczasem, the labeler captures images of GS1 QR code labels via an industrial camera and transmits them to the industrial all-in-one computer for optical verification and anomaly detection. This means that higher computing performance ensures more efficient image recognition, which is crucial for the smooth operation of pharmaceutical production lines.

III. Preferowane produkty TouchThink IPC

In conclusion, the customer ultimately chose TouchThink’s wall-mounted X86 industrial all-in-one computer (Model: TPC-W11) as the core control unit, mainly due to its powerful computing capability, Możliwość rozszerzenia, and industrial-grade stability.

TouchThink’s wall-mounted all-in-one computer series includes a variety of products, supporting the Intel® computing platform. Customers can flexibly select models based on their structural and performance requirements.

Novel and aesthetical design

Exlusive board, stable performance

Enconomical and pratical

Supporting Intel®J1900/J4125/J6412/N Series/ I Series processor

Precise and Efficient Production Control

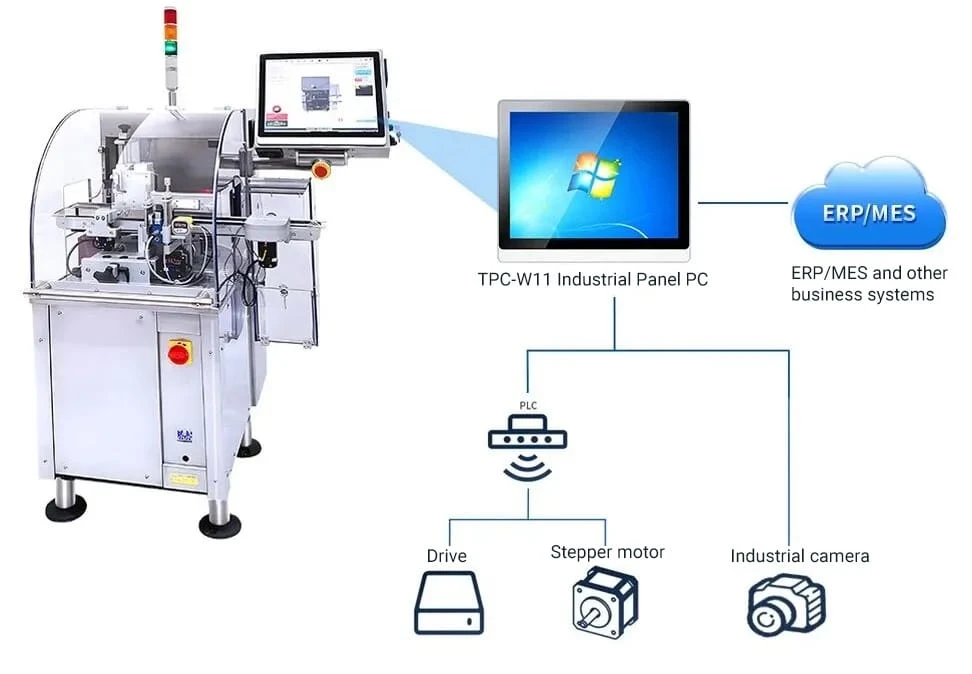

W tym przypadku, the TPC-W11 all-in-one computer accesses the network via LAN and can be integrated with the drug traceability system and enterprise ERP/MES systems. It generates a unique serial number label for each minimum packaged drug, while controlling automated marking and precise labeling.

Następnie, the machine vision system of the labeler needs to verify the label serial number. Equipped with a 10th Gen Intel® Core™ i7 quad-core processor and integrated UHD Graphics 620 GPU, the TPC-W11 supports the operation of the customer’s AI vision system. It efficiently verifies and processes the label image data collected by the industrial camera, and rejects boxes with abnormal labels.

Matching with the large storage combination of 8GB + 512GB, the TPC-W11 AIO Panel PC can automatically record information such as marking data, verification results, and operation logs for each batch, meeting the drug traceability requirements.

The TPC-W11 AIO touchscreen PC supports 10.1″–23.8″ high-definition capacitive touchscreens, with 10-point touch and glove-friendly touch functionality. Operators can easily set label parameters or modify label specifications via the panel to quickly switch between small-batch orders, meeting the needs of cost-effective and efficient flexible production.

After applying this solution, the customer’s labeler can achieve a maximum output of 200 units per minute, significantly shortening the production cycle.

Rich and Flexible Expansion Solutions

The TPC-W11 features a design with multiple serial ports, multiple network ports, and multiple USB ports, while supporting I/O customization and upgrades. In the customer’s project, the standard dual network ports of the TPC-W11 could not meet the customer’s labeler’s requirement to connect simultaneously to the PLC, industrial camera, czujniki, and other peripheral devices. We additionally upgraded 2 USB-to-Ethernet adapters for the customer, enabling easy centralized management of multiple devices and production line integration with highly flexible application.

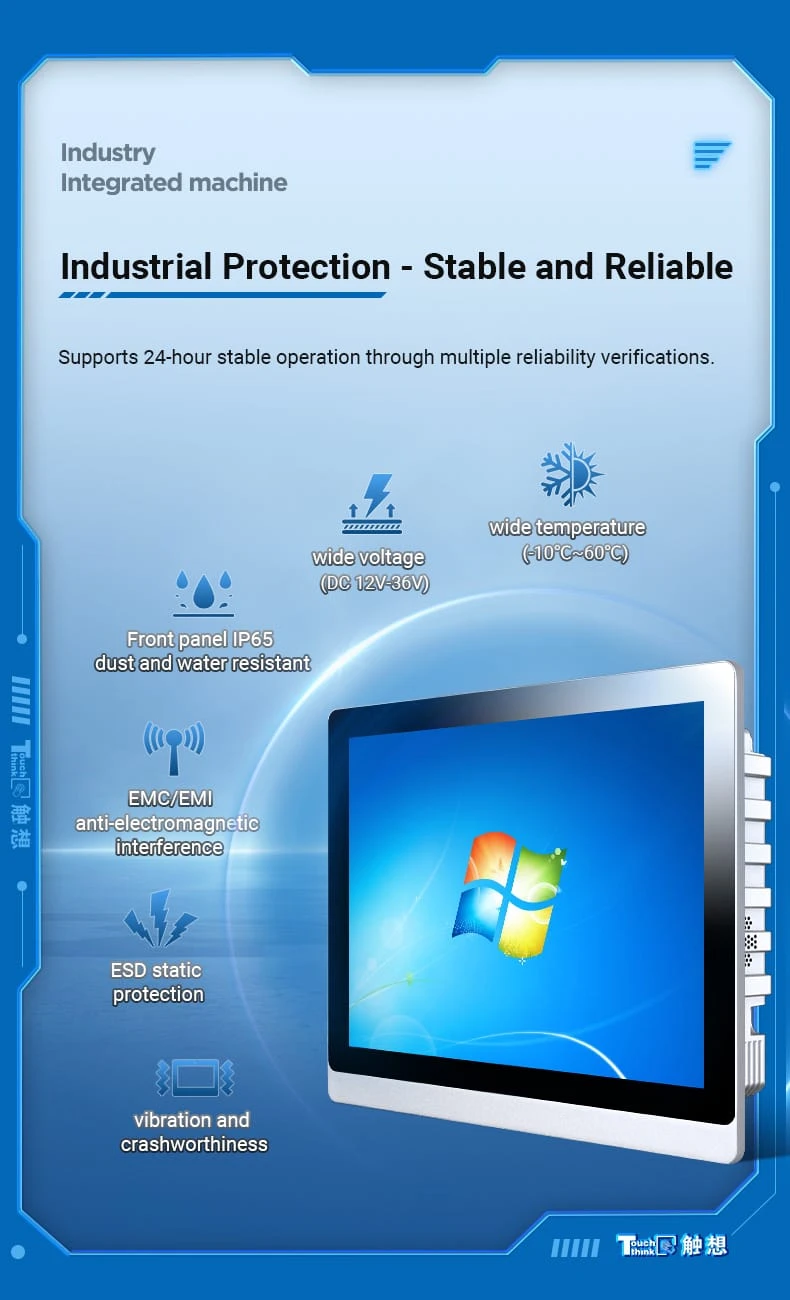

Meeting the Requirements of Clean Environments for Pharmaceutical Packaging

The TouchThink All-in-one Panel PC is equipped with an IP65 dustproof and waterproof flat front panel, making it easy to clean and maintain. Its enclosed fanless chassis design, combined with a rugged aluminum alloy rear cover, reduces the impact of dust and chemical corrosion—fulfilling the quiet and dust-free application needs of precision pharmaceutical workshops.

Dodatkowo, the TPC-W11 supports wide-temperature (-10℃ ~ 60 ℃) i szerokonapięciowe (DC 12 V-36 V) działanie. It has passed safety certifications for vibration resistance, interference resistance, and electrostatic protection, że 24/7 nieprzerwane wsparcie operacyjne.

Iv. Charakterystyczne zalety TouchThink

TouchThink industrial all-in-one computers are applied to labeler equipment. Their compact structure, multi-level configuration, and expandable design well meet the high requirements for automated control in the packaging field.

With reliable product quality and excellent technical support services, TouchThink further helps customers improve production efficiency, reduce costs in equipment replacement, labor, and time, and enhance their market competitiveness.