TouchThink Visual Depalletizing & Palletizing Solution: Expandable Industrial Computer + Panel-mounted Industrial Display For Smart Warehousing Applications!

Industrie Overview

Depalletizing and palletizing are critical processes in warehousing operations. Due to high labor intensity and repetitive tasks, manual work cannot be sustained long-term, often becoming an efficiency bottleneck that restricts the development of an enterprise’s supply chain. To gain efficiency and cost advantages in the fierce market competition, more and more enterprises are introducing depalletizing and palletizing robots into the intelligent transformation of warehousing. These robots can replace manual labor to efficiently and accurately complete warehousing tasks such as goods storage, outbound delivery, and production line feeding, offering excellent economic benefits.

Industrie Requirements

Through visual recognition, AI algorithms, and motion planning, depalletizing and palletizing robots convert the originally unordered and inefficient depalletizing/palletizing processes into high-precision, high-speed, and highly automated standard operations. Behind this transformation lies the support of stable, high-performance industrial computers and interactive hardware. Summarizing from its numerous practical cases, TouchThink has identified that depalletizing and palletizing robots generally face the following challenges:

- Visual Processing: Depalletizing and palletizing robots need to connect to 3D cameras for real-time image acquisition and processing, which places high demands on the CPU/GPU computing power of industrial computers.

- Flexible Operations: Faced with challenges such as a large number of SKUs, complex packaging, and varied pallet configurations, industrial computers must support the robot’s AI algorithms to output optimal depalletizing/palletizing strategies.

- Hardware Integration: Industrial computers need to coordinate the robot’s multi-axis motion control, visual acquisition, and communication systems, requiring high expandability.

- Continuous Stability: Industrial computers must be stable and reliable to adapt to complex warehousing environments and uninterrupted depalletizing/palletizing operations.

Recommended TouchThink IPC Products

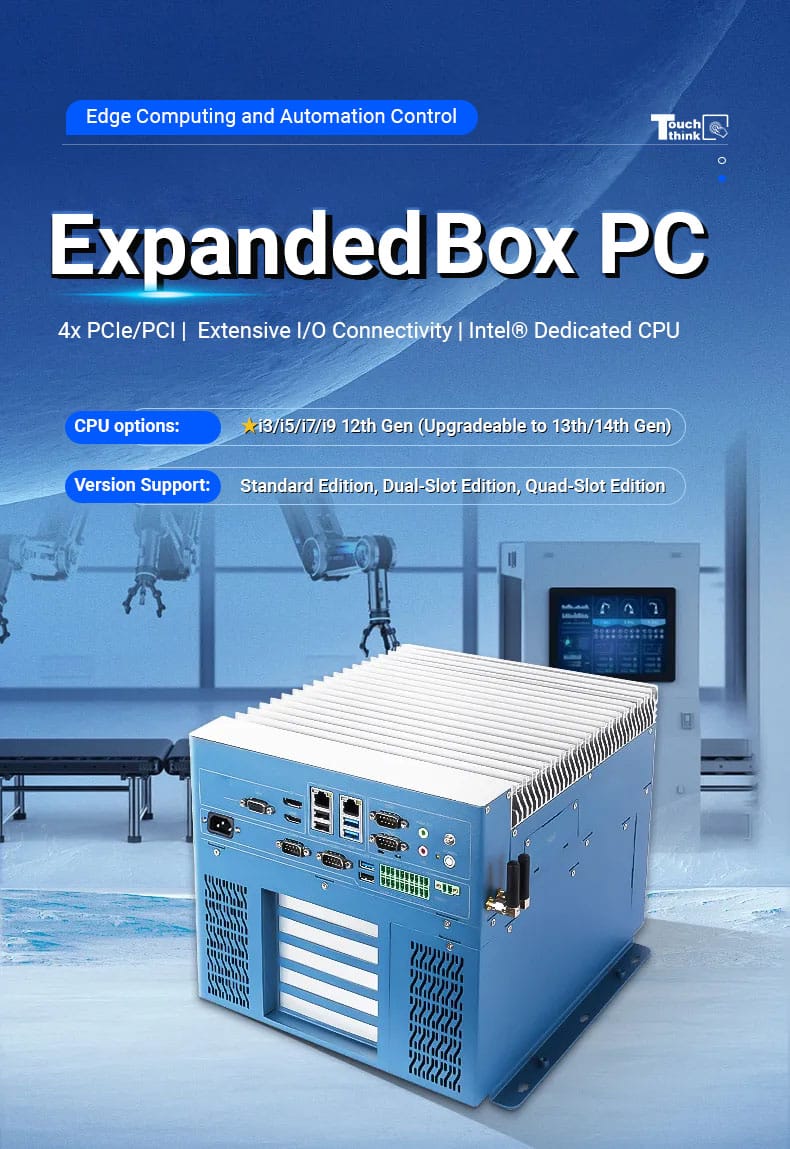

TouchThink Expandable Industrial Computer TPC07-WIPC + Embedded Industrial Display TPC-M28 solution is specifically launched for supporting intelligent warehousing depalletizing and palletizing robots. Its performance and reliability have been verified through multiple key terminal projects.

△ TouchThink’s Depalletizing & Palletizing Robot Solution

Powerful Computing Support

The TPC07-WIPC supports Intel® 12th/13th/14th Gen Core™ i3/i5/i7/i9 processors, integrates a high-performance GPU, and offers a maximum of 64GB DDR5 high-speed memory. It delivers outstanding intensive computing and graphics processing capabilities, easily handling parallel processing of multi-camera data and deep learning inference tasks, thus meeting the operational efficiency requirements of depalletizing and palletizing robots.

△ Powerful Edge Computing Performance of TPC07-WIPC

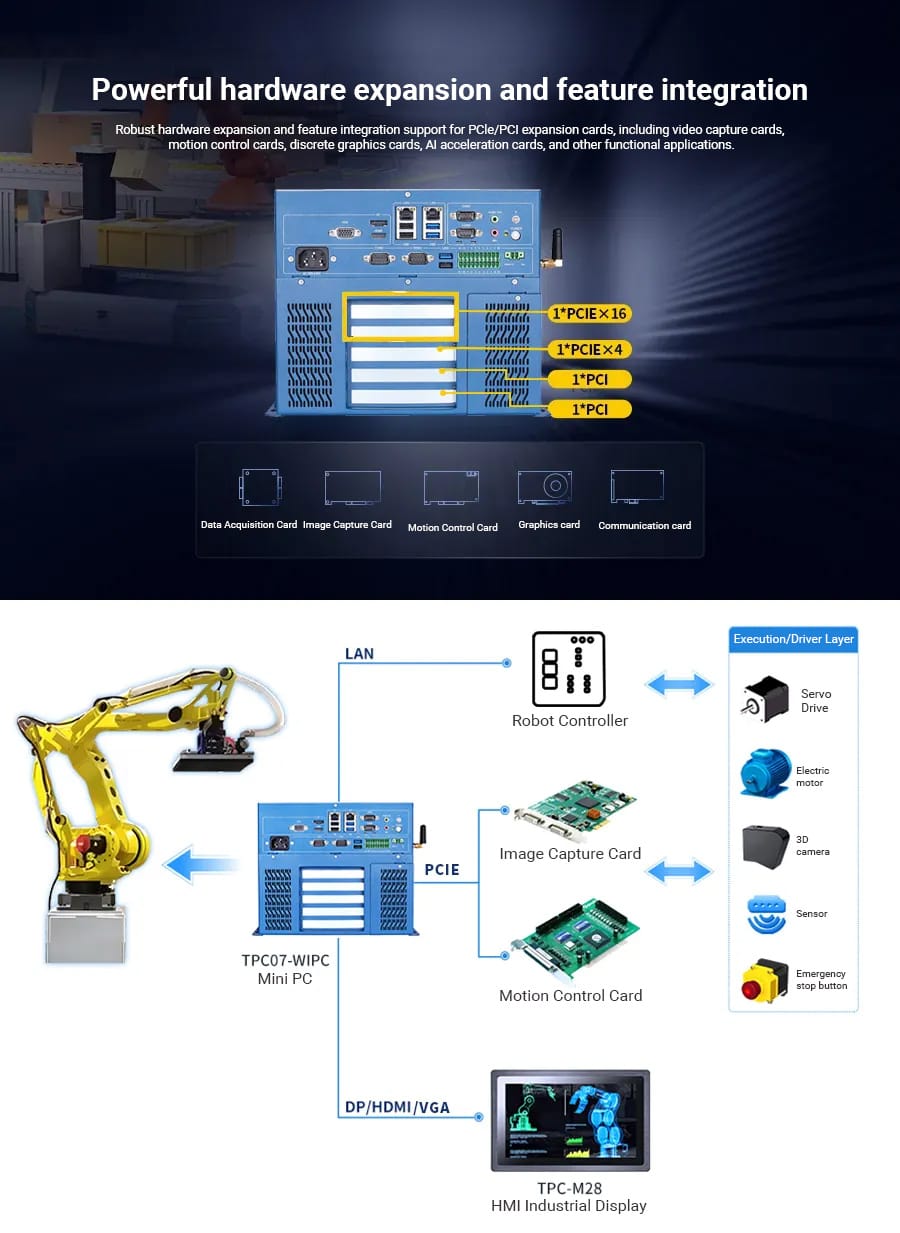

Rich Expansion & Integration

Another highlight of this solution is the TPC07-WIPC’s strong flexible expandability:

- It is equipped with up to 4 PCIe/PCI high-speed slots, supporting the expansion of discrete graphics cards, Bilderfassungskarten, Bewegungssteuerungskarten, usw. This further enhances the inference performance of AI visual algorithms in intelligent recognition, intelligent grasping, and motion planning for depalletizing and palletizing robots.

- With 6×USB ports, 4×COM ports, and 16-bit isolated GPIO, it supports 2.5Gbps & Gigabit dual-network redundancy + WiFi/Bluetooth. This greatly simplifies the integration difficulty of peripheral devices such as sensors and actuators, while improving the real-time sensing accuracy of multi-axis robotic arms and the efficiency of depalletizing/palletizing.

△ Structure of TouchThink’s Visual Depalletizing & Palletizing Solution

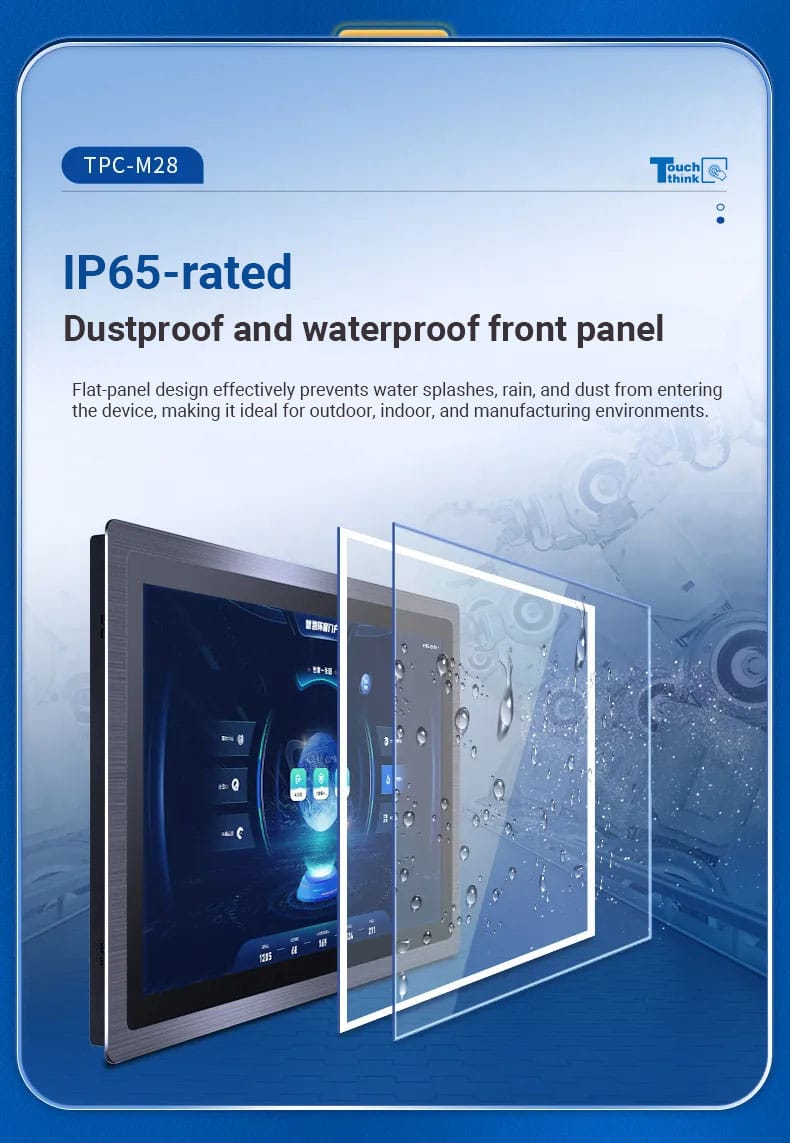

Efficient Human-Machine Interaction

In this supporting solution, the TPC-M28 industrial display serves as the interaction interface for depalletizing and palletizing robots. It supports FHD (Volle High-Definition) display and 10-point responsive touch control, enabling operation even with gloves. Through the TPC-M28, customers can monitor, set, and switch programs at any time, adapting to flexible depalletizing/palletizing tasks with high mix and small batches. It features an IP65 dustproof and waterproof front panel and an all-metal housing that resists vibration and impact.

△ High-Quality Interactive Performance of TPC-M28

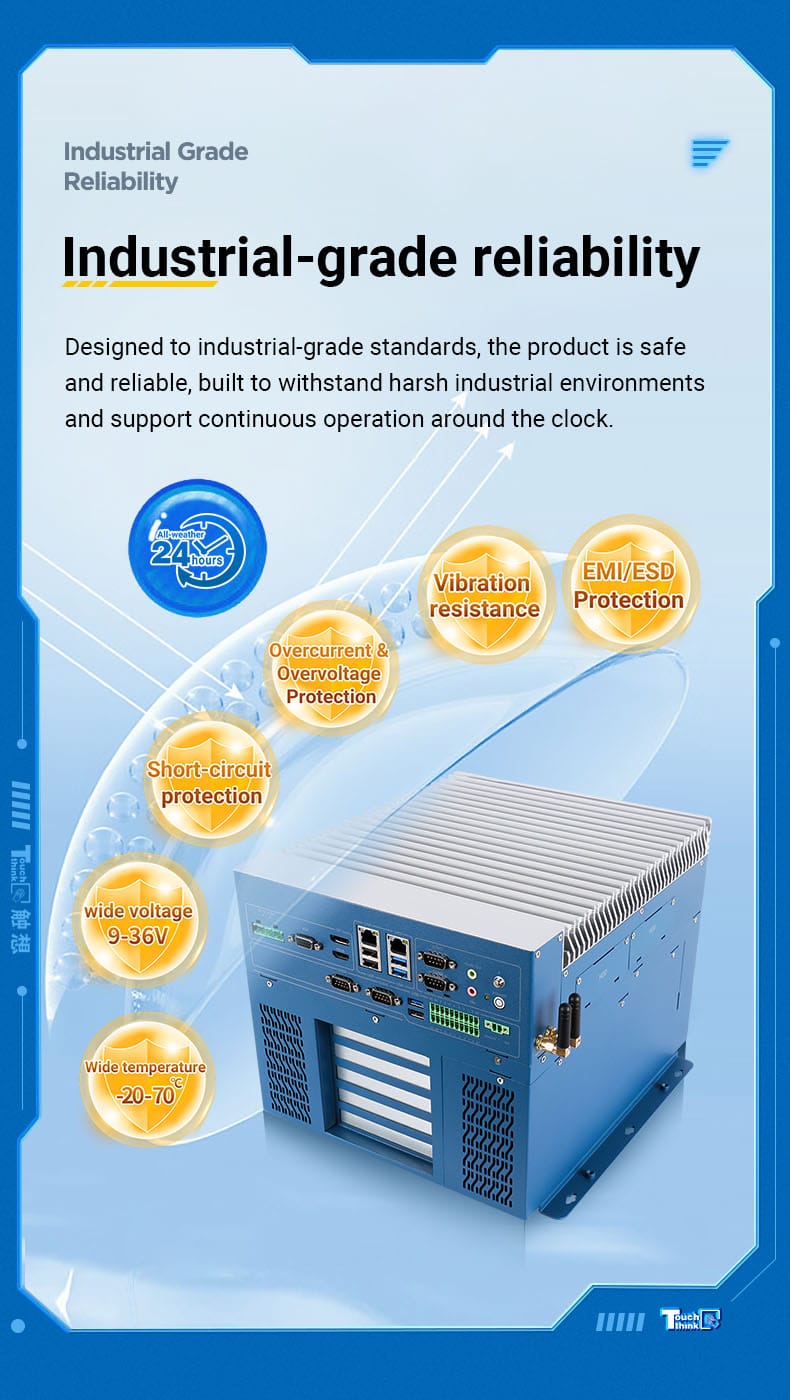

24/7 Reliable Operation Guarantee

TouchThink’s industrial computers and industrial displays all adopt custom board designs, with a streamlined and compact internal structure, no redundant wiring, and stable heat dissipation. They support a wide temperature range of -20℃~70℃, and provide comprehensive protection including overvoltage/overcurrent protection, short-circuit prevention, Vibrationsfestigkeit, impact resistance, und EMI/ESD-Schutz. This ensures 24/7 uninterrupted operation, enabling long-term safe and reliable performance even in harsh warehousing environments.

△ Industrial-Grade Stability & Reliability of TPC07-WIPC

Touchshink Industrial Touchscreen Panel PC -Leistungen

TouchThink’s depalletizing and palletizing robot solution has been widely applied in the logistics and warehousing fields of industries such as e-commerce, Pharmazeutika, and FMCG (Fast-Moving Consumer Goods). It addresses core pain points in warehouse management, such as efficiency and cost issues, and provides strong support for the digital transformation of intelligent warehousing and the stability of supply chains.