PC All-in-one industriale touchphink: Monitoraggio di precisione & Aggiornamenti intelligenti Rilevamento della batteria a ciclo completo nella nuova rivoluzione energetica

Panoramica dello sviluppo del settore

Le batterie agli ioni di litio sono ampiamente utilizzate nei nuovi veicoli energetici, sistemi di accumulo di energia, ed elettronica di consumo. Negli ultimi anni, I punti chiave per migliorare la batteria al litio r&D e produzione si sono concentrati principalmente sulla capacità della batteria, velocità di ricarica, Vita ciclo, e sicurezza, Tutti i quali sono correlati alla conduttività della batteria.

Il tester di resistenza al polo è uno strumento di precisione appositamente progettato per misurare la qualità conduttiva delle batterie al litio. Il pezzo di palo qui è il componente centrale degli elettrodi positivi e negativi delle batterie agli ioni di litio, e la resistenza è l'indicatore chiave per quantificare la conduttività della batteria.

Perciò, Il tester di resistenza al polo è diventato uno strumento importante per la ricerca scientifica della batteria e il monitoraggio del processo di produzione.

Ii. Requisiti dell'applicazione del progetto

I computer all-in-one industriali svolgono ruoli importanti nei tester di resistenza al polo, compreso il controllo dell'elaborazione, Gestione dei dati, e interazione dell'utente. Le prestazioni del PC all-in-one sono fondamentali per la stabilità e la precisione del tester. Quando si cerca il PC all-in-one di livello industriale., I clienti hanno i seguenti requisiti:

- Sufficiente potenza di calcolo per eseguire processi di misurazione automatica e attività di elaborazione dei dati in tempo reale.

- Grande capacità di archiviazione per garantire la registrazione batch e l'archiviazione dei dati di misurazione.

- Abbondanti terminali industriali per consentire la connessione del segnale tra sensori e attuatori.

- Supporto per il networking per accedere al sistema MES, Facilitare il giudizio ausiliario della linea di produzione e la tracciabilità della qualità.

- Severi requisiti di schermatura elettromagnetica e messa a terra per evitare interferenze esterne che influenzano l'accuratezza della misurazione.

Iii. Prodotti IPC a touchthink preferiti

La serie Z touchthint ha incassato il PC All-in-one industriale TPC-W28 dimostra una forte adattabilità e vantaggi competitivi in molteplici aspetti, ed è stato applicato e abbinato in vari tester di resistenza dei clienti:

CPU quad-core + Efficienza di misurazione del potenziamento dell'aggiornamento dell'archiviazione

In questa soluzione, Il computer tutto in uno di Touchthint Industrial è alimentato dal processore Intel Quad-Core J4125, Abbinato a 4 GB DDR4 aggiornato + 128GB SATA Accelerated Storage. Abilita l'elaborazione in tempo reale di dati di punti multi-probo e segnali di controllo sincroni, Supporta analisi rapide e output delle mappe delle nuvole di distribuzione della resistenza, e soddisfa i requisiti di misurazione continua delle linee di produzione della batteria, migliorando così l'efficienza complessiva. Il modello TPC-W28 offre anche configurazioni opzionali con J6412, N97/N100/N150/N200/N355, e core ™ 8 ° e 13 ° processori della serie I per soddisfare le diverse esigenze di performance.

Interfaccia ricca e funzionalità di rete

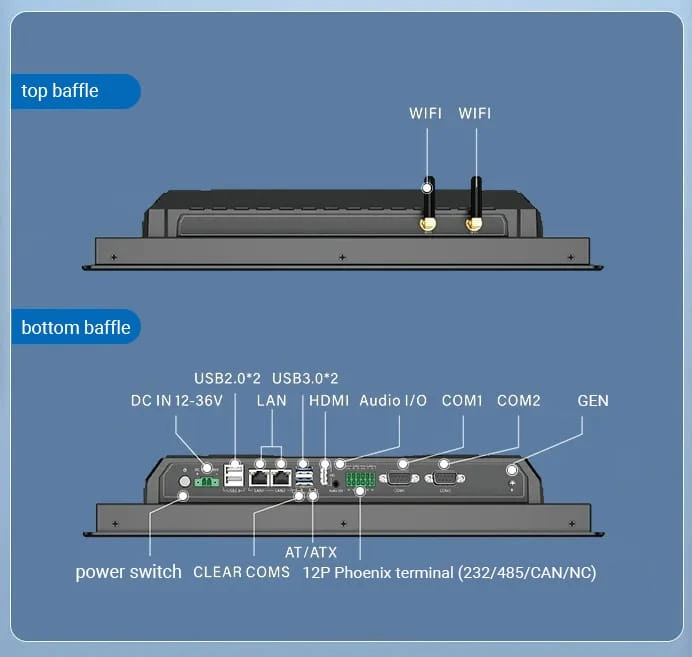

Il TPC-W28 viene fornito di serie con 4 × USB, 2× GBE, 12-Pin Terminali industriali, e comunicazione porta porta. Può raccogliere dati in tempo reale da sensori come i servi motori, sensori di pressione/temperatura/spostamento per controllo ad alta precisione, e supporta connessioni a periferiche come stampanti e dispositivi di archiviazione, Migliorare la flessibilità e la scalabilità dei sistemi di test. Inoltre, Il TPC-W28 supporta Dual Gigabit Ethernet + 3Comunicazione g/4g o wifi, Abilitazione del caricamento in tempo reale di dati di test ai sistemi MES. Può inoltre integrare i dati dal rivestimento/rolling machine per la sincronizzazione del database e la gestione remota, facilitare l'ottimizzazione del processo.

Protezione rigorosa di livello industriale

Il TPC-W28 presenta ampia temperatura (-10℃ ~ 60 ℃) e ampia tensione (CC 12 V-36 V) capacità, nonché rigorose interferenze anti-elettromagnetiche EMC/EMI e design antistatici ESD. Può formare una protezione di schermatura elettromagnetica unificata con l'intero sistema di misurazione, impedire l'interferenza esterna di influire sulla precisione del test e sulla sicurezza delle attrezzature.

Conveniente & Interazione a schermo regolare

Il TPC-W28 viene preinstallato con Windows 10 sistema operativo, Garantire un funzionamento regolare del software di misurazione dei clienti. Dotato di un 10.1” touchscreen capacitivo a 10 punti ad angolo di ampio visti, Facilita un'impostazione dei parametri di prova facile, Anteprima dei dati, e monitoraggio dei processi. Il suo design esterno è specificamente personalizzato per dispositivi montati su mobili, Con un pannello frontale sottile da 3 mm che si integra perfettamente negli armadi per un'installazione sicura ed esteticamente piacevole.

IV. I vantaggi distintivi di Touchthink

TOUCKHINK INDUSTRIAL All-in-One Computer, Con tre principali vantaggi dell'affidabilità hardware, Facile integrazione, e scalabilità, sono stati ampiamente applicati in scenari di rilevamento di precisione come l'ispezione del materiale a semiconduttore, Misurazione dell'immagine ottica, Ispezione visiva AI, e misurazione elettronica, Empowering profondamente processi chiave nel settore manifatturiero.