TouchThink Industrial PC'ler, modern fabrikalar inşa etmek için mobil işbirlikçi robotları güçlendirin

Sanayi Geliştirme Arka Planı

Sanayi Altında 4.0, İmalat sanayi, geleneksel seri üretimden, kısa döngülerle karakterize edilen esnek bir üretim modeline geçmiştir., küçük partiler, ve özelleştirme. Bu dönüşüm özellikle aşağıdaki sektörlerde belirgindir: 3C (Bilgisayarlar, İletişim, ve Tüketici Elektroniği), otomotiv elektroniği, Ve yarı iletken ambalaj, üretim hatlarının sık sık malzeme yüklemesi gerektirdiği yerler, toplu taşıma, toplantı, ve süreç ayarlamaları. Fakat, geleneksel robotik kollar ve AGV ekipmanı genellikle sabit işlemlerle veya tek işlevlerle sınırlıdır.

Üretim verimliliğini ve etkinliğini daha da artırmak için, üreticilerin benimsemesi gerekiyor daha dinamik, çevik operasyonel konfigürasyonlar.

Mobil işbirlikçi robotların devreye girdiği yer burasıdır. Bu gelişmiş robotlar, insanlar gibi işlev gören “eller, ayak, gözler, ve beyinler,” AGV'lerin mobilitesini robotik kol işlevselliğiyle entegre edin. Performans sergileyebilirler çok fonksiyonlu, bölgeler arası görevler, Daha karmaşık ve uyarlanabilir üretim süreçlerine yönelik artan ihtiyacın karşılanması.

Proje başvuru şartları

Müşterinin mobil işbirlikçi robotunun temel teknolojileri, makine görüşünü kapsar, otonom navigasyon, hareket algısı, ve robotik kol kuvveti kontrolü. Robotun mobil şasisi ve robotik kollarının çok eksenli işbirliğini doğru bir şekilde kontrol etmek için, güçlü bir endüstriyel bilgisayar “beyin” veri işleme ve gerçek zamanlı karar verme görevlerini hızla tamamlamak için gereklidir.

Endüstriyel PC'ler yüksek kare hızlı kameralar ve silindirler ve motorlar gibi mekanik kollu aktüatörlerle koordineli çalıştığında, görüntü edinme kartları Ve hareket kontrol kartları Hassasiyet ve verimlilik sağlamak için gereklidir. Öyleyse, . PCI genişletme yeteneği Bu operasyonel ihtiyaçları karşılamak için endüstriyel PC vazgeçilmezdir.

TouchThink IPC Ürün Çözümleri

Bu talepleri karşılamak için, TouchThink şunları sunar: yüksek performanslı, genişletilebilir endüstriyel PC çözümü içeren TPC06-WIPC endüstriyel PC ile birleştirildi TPC101-M2 gömülü endüstriyel monitör. Bu çözüm, mobil işbirlikçi robotların ihtiyaçlarına tam olarak uyarlanmıştır, kullanım için güvenilir akıllı ekipman sağlamak üretim atölyeleri, depolar, ve diğer endüstriyel senaryolar.

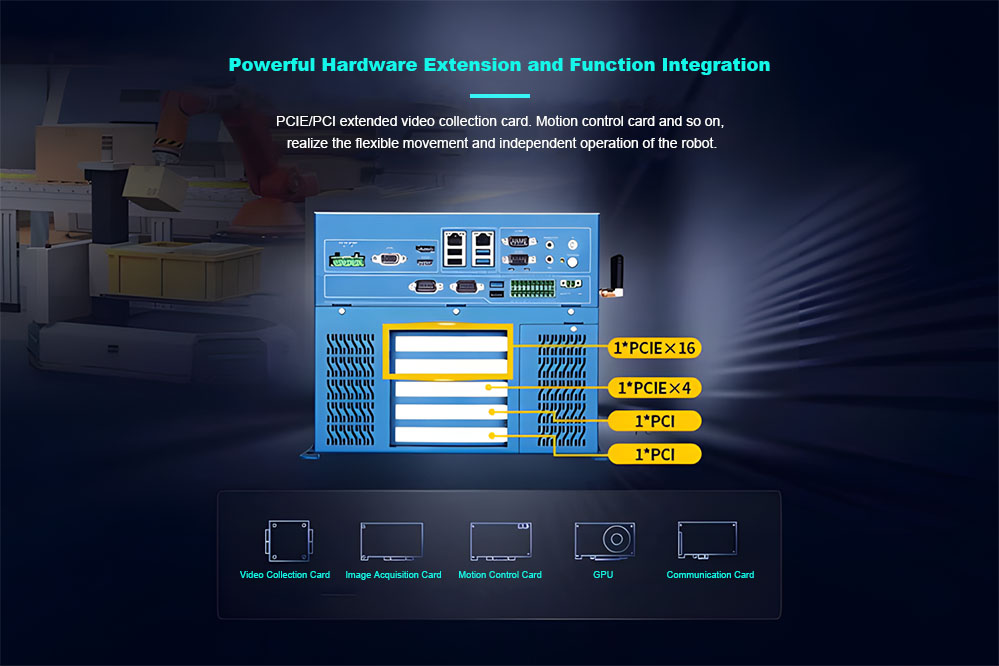

1. Sağlam ve Esnek Donanım Genişletme ve İşlevsel Entegrasyon

Bu çözümdeki TPC06-WIPC endüstriyel PC aşağıdaki özelliklerle donatılmıştır: 16-kanal yüksek hızlı PCIe arayüzü Ve bir 32-bit PCI yuva, video görüntüsü alımının kusursuz entegrasyonuna olanak tanır, hareket kontrolü, ve G/Ç genişletme kartları. Ek olarak, içerir:

- 6 USB bağlantı noktaları

- 4 seri bağlantı noktaları

- 16-bit izole GPIO

Bu çeşitli bağlantı, aşağıdakilerin kontrolünü ve entegrasyonunu destekler: motorlar, kameralar, sensörler, lazer tarayıcılar, anahtarlar, ve diğer cihazlar. Bu özelliklerle, Endüstriyel PC, mobil işbirlikçi robotların performans göstermesini sağlar esnek ve otonom operasyonlar, modern üretim ortamlarının karmaşık taleplerini karşılamak.

2. Üstün Performans ve Verimlilik Güvencesi

The TPC06-WIPC endüstriyel PC destekler 12bu, 13bu, ve 14. nesil Intel® Core™ i3/i5/i7/i9 işlemciler, zorlu görevler için olağanüstü bilgi işlem gücü sağlar. Yüksek iş yükleri altında performansı artırmak için, teklif ediyor:

- Çift DDR5 bellek modülleri daha hızlı veri işleme için

- Kapsamlı depolama genişletmesi ile:

- 2 SATA 3.0 port

- 1 mSATA yuvaları

- 1 M.2 yuvası

Bu sağlam konfigürasyon, mobil işbirlikçi robotların yüksek performans ve yanıt verme hızı, karmaşık ve sürekli görevleri yerine getirirken bile. Bu özellikler sorunsuz çalışmayı garanti eder, güvenilir veri yönetimi, ve hızlı görev yürütme, çözümü ideal hale getiriyoruz yüksek talep gören endüstriyel ortamlar.

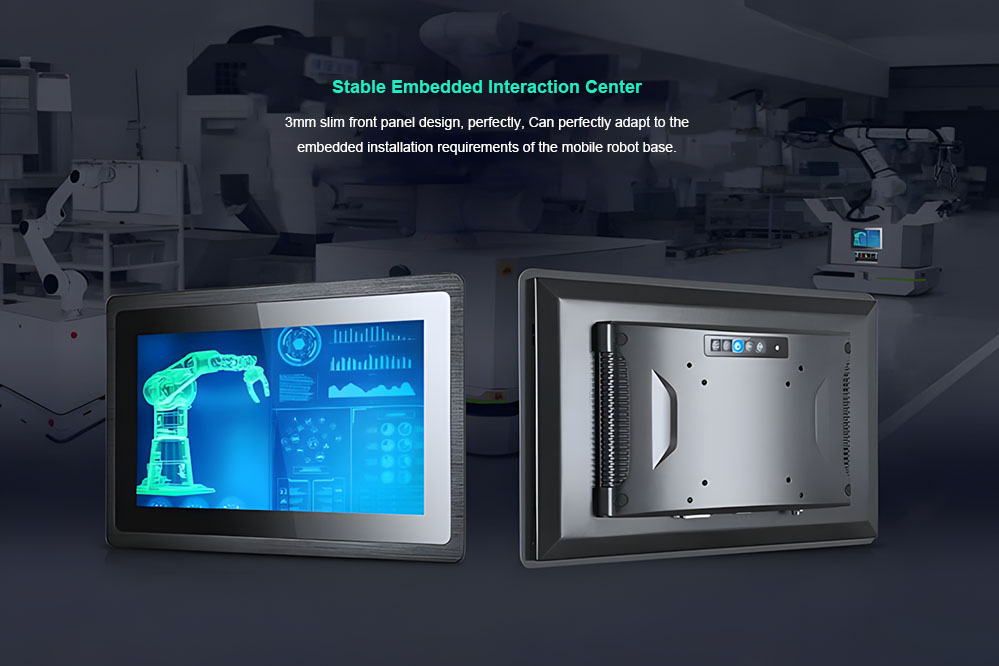

3. Güvenilir Yerleşik Etkileşim Merkezi

Eşlik eden TPC116-M2 endüstriyel monitör özellikler bir 3mm ultra ince ön panel tasarımı, mobil robot platformlarına gömülü kurulum için mükemmel uyum sağlar. Bu tasarım şunları sağlar: hareket sırasında stabilite, hatta karmaşık rotalar.

TPC116-M2'nin temel özellikleri şunları içerir::

- FHD tam yüksek çözünürlüklü ekran Kristal netliğinde görsel geri bildirim için

- 10-nokta dokunma desteği, kolaylaştırıcı:

- Gerçek zamanlı izleme çalışma koşulları

- Yol düzenleme mobil robotlar için

- Yazılım etkileşimi insan-makine işbirliği için

Bu sağlam etkileşimli merkez, kullanılabilirliği ve verimliliği artırır, Operatörler ve mobil robotlar arasında kusursuz koordinasyonun sağlanması, dinamik endüstriyel ortamlarda bile.

Birden Fazla Sektörde İnovasyonu Desteklemek

Mobil işbirlikçi robotlar tarafından desteklenmektedir TouchThink endüstriyel PC'ler çeşitli alanlarda tüm potansiyellerini ve yeniliklerini açığa çıkarıyorlar. Bu çözüm çok sayıda müşterinin ticari başarı gibi sektörlerde:

- Hassas üretim

- Yarı iletkenler

- 3C ve otomotiv elektroniği

- Biyomedikal uygulamalar

- Yeni enerji çözümleri

Gelişmiş teknolojisi ve çok yönlü yetenekleriyle, TouchThink'in çözümleri fabrikaların ve endüstriyel operasyonların benimsenmesini sağlıyor esnek, çevik iş akışları, yeni verimliliklerin ve iş değerinin kilidini açıyor.