TouchThink Industrial Monitor Solutions on the Automobile Assembly Production Line

Background of Industry Development

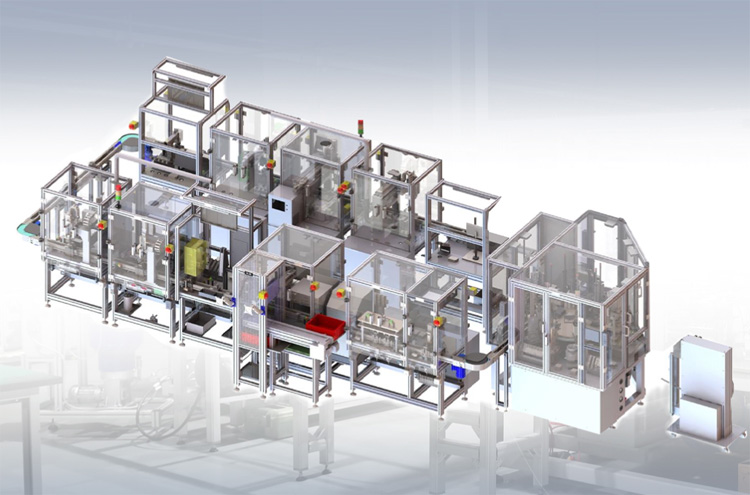

Behind the booming sales in the automobile industry lies the support of an advanced production and assembly system. From auto parts to complete vehicles, the production and technological processes of automobiles are becoming increasingly complex, and more and more automated assembly and inspection equipment are involved.

Project Application Overview

The use of industrial monitors to assist with applications such as automated production, quality inspection, and process monitoring on automobile assembly lines can guarantee production efficiency and quality and reduce operating costs.

An Chinese automation equipment manufacturer has deployed the TouchThink embedded industrial monitor TPC-M2 for its automobile parts assembly and testing equipment. With its robust and reliable hardware design and large-screen interface, it can not only play a crucial role in information insight and control interaction but also help operators respond quickly and adjust the operation of the equipment flexibly, thus possessing excellent application value.

TouchThink Product Solutions

Due to the diverse automobile assembly processes and the numerous types of customers’ automated production lines and non-standard automated special machines and equipment, the TPC-M2 monitors of various specifications such as 12″, 15.6″, 17.3″, and 19″ were selected for this project, all of which have achieved efficient and reliable operation.

Flexible Integrated Management to Enhance Production Line Efficiency

The TouchThink TPC-M2 industrial monitors have a size range from 7″ to 23.8″ and flexible installation methods (embedded/wall-mounted/cantilever-mounted/jib-mounted, etc.). They can be integrated with almost all automated equipment in the automobile production and assembly process, meeting the installation requirements of various workshop scales, making the application more convenient and efficient.

Highly Precise Multi-Touch Technology

The TPC-M2 adopts 10-point capacitive touch technology, supporting control responses without delay. The industrial-grade panel can provide customized enhanced performances such as FHD full high definition, high brightness, a 178° full viewing angle, and touch operation while wearing gloves. It is conducive to centralized management and displaying data of various key links in automobile production and assembly, making it highly suitable for industrial control and interactive applications.

Highly Reliable Industrial-Grade Design

The TPC-M2 uses high-strength, lightweight, highly thermally conductive, and interference-resistant aluminum alloy as the main raw material for its outer shell. The metal wire-drawing and die-casting processes endow the TPC-M2 with a strong industrial texture and the advantage of structural stability. Inside, it is carefully equipped with military-grade components. Coupled with the enclosed design and shock-absorbing layout, it can withstand environmental challenges and potential threats such as mechanical shocks, water vapor and dust intrusion, EMI/EMC interference, and changes in high and low temperatures, meeting the standards of durability and reliability.

Connection Optimization Focusing on Stability

When delving into the application scenarios, we find that industrial control equipment is prone to be interfered by voltage fluctuations during use, and common application pain points such as poor contact and loose connections also exist. Based on this, the TouchThink TPC-M2 industrial monitor adopts a wide voltage input of DC12V – 36V, adapting to various load conditions. Meanwhile, the DC connector is designed with threaded anti-loosening features, and the touch interface applies RJ45 pin locking, ensuring a firm connection and guaranteeing the efficient and stable operation of the production line equipment.

Background of Industry Development

he TouchThink industrial monitor adopts a self-developed industrial-grade driver board, integrating various industry application requirements, which can achieve universal adaptation and extensive compatibility, helping customers’ projects to be implemented quickly. Meanwhile, thanks to the powerful R&D resources and the scale manufacturing advantages of the direct sales and production chain, TouchThink provides batch purchasing and flexible customization services, which can accurately match customers’ needs and possess more cost advantages.

One-stop IPC Hub

One-stop IPC Hub