WA: +86 186 6580 4491 | Email: info@touchthink.net

More Language is Comming!!!

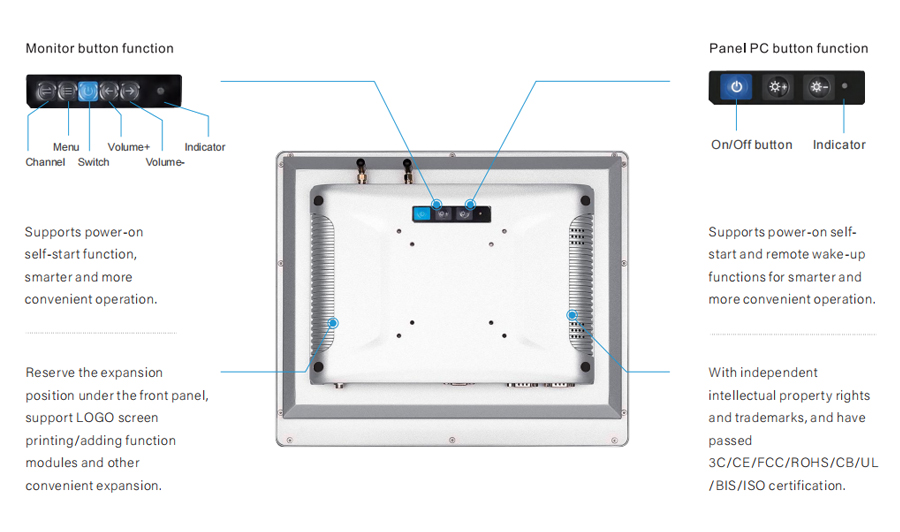

The 4th Gen A Series industrial monitor has a 10mm thickness for the front panel, featuring excellent impact resistance performance, suitable for wall hanging, desktop stand, and VESA installation. With front IP65 panels. Ideal for both commercial and industrial automation applications, including POS, KDS, production automation, etc.

| Product Size | Resolution | Aspect Ratio | Contrast Ratio | Brightness | Quick Inquiry |

|---|---|---|---|---|---|

| 10.1″ | 1280*800 | 16:10 | 1000:1 | 300 cd/m2 | Inquiry Now |

| 10.4″ | 1024*768 | 4:3 | 1000:1 | 400 cd/m2 | Inquiry Now |

| 11.6″ | 1920*1080 | 16:9 | 1000:1 | 300 cd/m2 | Inquiry Now |

| 12.0″ | 1024*768 | 4:3 | 1000:1 | 500 cd/m2 | Inquiry Now |

| 15.0″ | 1024*768 | 4:3 | 1000:1 | 300 cd/m2 | Inquiry Now |

| 15.6″ | 1920*1080 | 16:9 | 800:1 | 300 cd/m2 | Inquiry Now |

| 17.0″ | 1280*1024 | 5:4 | 1000:1 | 300 cd/m2 | Inquiry Now |

| 17.3″ | 1920*1080 | 16:9 | 600:1 | 300 cd/m2 | Inquiry Now |

| 19.0″ | 1280*1024 | 5:4 | 1000:1 | 300 cd/m2 | Inquiry Now |

| 19.1″ | 1440*900 | 16:10 | 1000:1 | 300 cd/m2 | Inquiry Now |

| 21.5″ | 1920*1080 | 16:9 | 1000:1 | 300 cd/m2 | Inquiry Now |

| Product Features |

|---|

| Product Parameters | ||

|---|---|---|

| Hardware Parameters | CPU | RTD2513 |

| Material | Aluminum alloy | |

| Menu Language | Multilingual (default: English) | |

| Key Function | AUTO/MENU/POWER/LEFT/RIGHT | |

| Color | Sliver | |

| Video Input PC-RGB | Format Up to 1920*1080@60HZ, PC-RGB: Color 16bit, 24bit, 32bit | |

| Touch Parameters | Projection capactivite touch Touch Point: 10-point Light Transmittance: >=88% Input Mode: handwriting or capactivite pen Standard Protocol:USB | Resistive touch 4-5wire/5 Wire Touch Point: single point Light Transmittance: >=78% Input Mode: Fingertip or stylus Standard Protocol:USB | Non-touch Light Transmittance: >=92% | ||

| Interface Parameters | DC Port | 1*DC2.1(DC 12-36V) |

| HDMI | High-definition audio digital signal transmission, support HDMI data input. | |

| VGA | Analog signal transmission, support VGA best resolution. | |

| DVI | Digital signal transmission, support the best resolution of DVI digital signal. | |

| Touch Interface | RJ45 interface standard(defined as USB), compatible to capacitive/resistive touch | |

| Audio interface | 1*Audio I/O, Support audio input and output |

| Environment Parameters | Working Temperature | -10°C~60°C |

| Storage Temperature | -20°C~70°C | |

| Relative Humidity | Humidity: 95% Non-Condensing | |

| Vibration Protection | IEC 60068-2-64, Random, 5 ~ 500 Hz, 1 hr/axis | |

| Impact Protection | IEC 60068-2-27, Half sine wave, Lasting for 11ms |

| Other Parameters | Power input | DC 12V~36V |

| Static power | 18W | |

| Installation Method | Supports snap-embedded,wall edbedded,wall mounted,desktop,louvered,cantilever-mounted,boom-mounted,etc. | |

| Warranty Policy | Three years ( one year free warranty ) |