Customized Solutions for TouchThink Ruggedized Industrial All-in-One PC in CNC Machine Tools, Boosting Processing and Production Efficiency

I. Overview of Industry Development

CNC technology is one of the most important processing technologies in modern manufacturing. It uses computer numerical control programs to operate machine tools, performing automated processing such as cutting, drilling, and tapping on metal/non – metal materials, meeting the application requirements of various industries for precision structural parts and components.

With the continuous upgrading and high-end development of the manufacturing industry, CNC machine tools need to undertake higher-precision, more complex, and flexible processing tasks. The development of numerical control systems has gradually focused on digital management. By means of real – time data interaction and process monitoring, the stability of the manufacturing process and production capacity can be improved, alleviating the problems of quality and efficiency in precision processing.

II. Project Application Requirements

In the entire CNC numerical control system, the numerical control panel is the most intuitive and convenient digital management unit. It integrates computer control technology, a visual interface, communication interfaces, and control buttons, etc., and can centrally process programs, analyze instructions, and control and manage the operation of the machine tool.

In pursuit of ultimate equipment performance, a foreign client hoped that TouchThink could customize a numerical control panel for its new CNC milling machine. The panel must meet the requirements of operation efficiency and environmental adaptability, and be supported by high – performance hardware at the same time.

III. Matched TouchThink Product

Combining its strong customized development capabilities, based on the hardware of the 5th Gen embedded industrial all-in-one PC TPC215-A5, TouchThink carried out comprehensive designs in appearance, structure, configuration, etc., accurately matching the client’s functional demands and successfully passing the project acceptance.

1. Personalized Panel, Intuitive Operating Experience

The TouchThink TPC215-A5 adopts a 21.5” FHD full-high-definition vertical screen with 10-point capacitive touchscreen, upgraded to a 178° full-view angle, providing a broader vertical field of vision and viewing angle. It can fully load the client’s personalized software interface, enhancing the visual effect and editing operation experience.

The customized enclosed rigid chassis is dust-proof, debris-proof, and oil-resistant, making it highly suitable for the manufacturing and processing environment. In addition, the TPC215-A5 also offers personalized development of the shell color, logo silk – printing, front – mounted buttons, and interfaces, enabling flexible adjustment of the appearance style and installation method to match diverse machine tool design schemes.

2. High – Performance Motherboard, Improving Machine Tool Production Efficiency

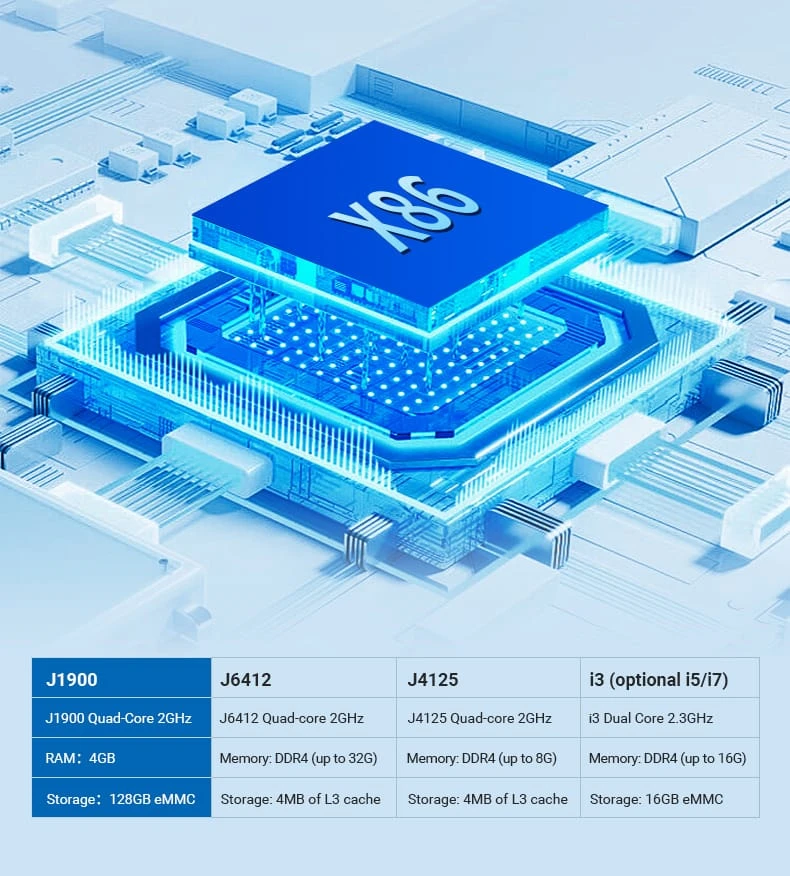

The TPC215-A5 is developed based on the X86 architecture and supports multi – level performance selection. In this case, the client selected the TouchThink CX-6U01 motherboard solution, equipped with an Intel® Core™ i5 processor with a main frequency of 2.3GHz, providing powerful computing power for the machine tool system. The large storage space of 4G + 128G can support the operation and storage of G – code files and large – scale programs.

In addition, the TPC215-A5 integrates IoT modules such as dual – gigabit LAN, 4G, and WiFi, as well as a rich variety of I/O interfaces, enabling remote operation, machine tool data collection, and equipment communication, achieving feed and positioning control of the spindle system and improving processing accuracy and production efficiency.

3. Robust Industrial Protection, Stable Mechanical Performance

The TPC215-A5 has been strengthened in design, with strict EMC/EMI electromagnetic interference resistance and ESD anti – static protection. It supports operation in a wide temperature range (-10℃~60℃) and a wide voltage range (12V – 36V), and can resist vibration, dust, oil, and high temperatures in the lathe working environment, ensuring long – term stable operation.

IV. Customer Project Benefits

The TouchThink industrial all-in-one panel pc provides reliable performance and operation guarantee for the CNC machine tool numerical control panel. With its strong customized capabilities, it brings economic and efficient product development support to the client, meeting their specific functional requirements and being highly recognized by the client.

In addition, TouchThink also provides one-to-one technical guidance, product training, and timely after-sales response, allowing the client to have no worries.

One-stop IPC Hub

One-stop IPC Hub